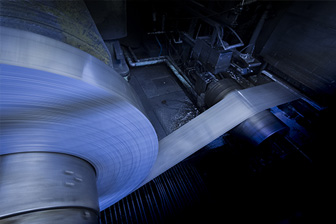

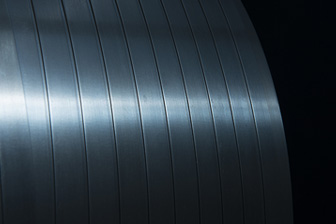

Cold roll laminating

SNAR has two rolling mills:

- one RWF with 470 mm maximum table width, 7 mm maximum and 0.4 mm minimum thickness

- one MINO with 450 mm maximum table width, 7 mm maximum and 0.4 mm minimum thickness

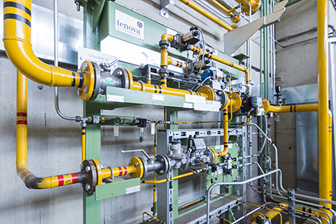

Heat treatments

SNAR carries out heat treatments with globular annealing and recrystallisation, using Tenova plants with 100% hydrogen atmosphere and Ebner plants with nitrogen atmosphere.

Skin-pass

Products are finished for special and close tolerances. The surfaces subjected to skin-pass are free from any imperfection.

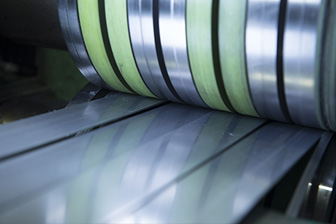

Classic ribbon slitting

Three different Cutting machines with 5 mm minimum and 400 mm maximum width.

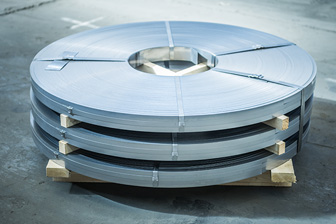

Oscilated wounded coils slitting

Strips cut as spiral wound coils are more productive than regular strips. The time needed for changing machines is drastically reduced because the coils can be 15 time longer than the strips, which makes for higher performance.

Cutting spiral wound coils with 5 mm minimum and 70 mm maximum width.

Round edges

Strips with hemmed, rounded or contoured edges.

A line for customer specified edges.

Grinding Center

Internal grinding center for rolls and blades.

Slitter 1500

SNAR carries out mother coil slittings for 1500 mm maximum length.

For information about products or services

Tel. +39 030 315497 / Email: [email protected]